Resonance woods

| Whether we call it resonance wood or luthier's

wood, we're talking here about wood used to manufacture instruments with the ability to vibrate to propagate sound through the air. It is mainly the soundboard which fulfills this role. Highly stressed by the tension and vibration of the strings, the soundboard is subjected to a great deal of pressure at the bridge. especially in the case of steel-string guitars, so it must also be sufficiently resistant. Lightness is also an essential criterion, so as not to increase the overall weight of the guitar and facilitate the propagation of sound waves. When it comes to these qualities, spruce is by far the best performer. European spruce in particular. European spruce, but not just any spruce, as the tree from which it comes must meet several criteria :

Spruce produces a rather bright, warm and soft sound with rich harmonics. Its strong vibratory power gives notes that last and propagate well. |

||

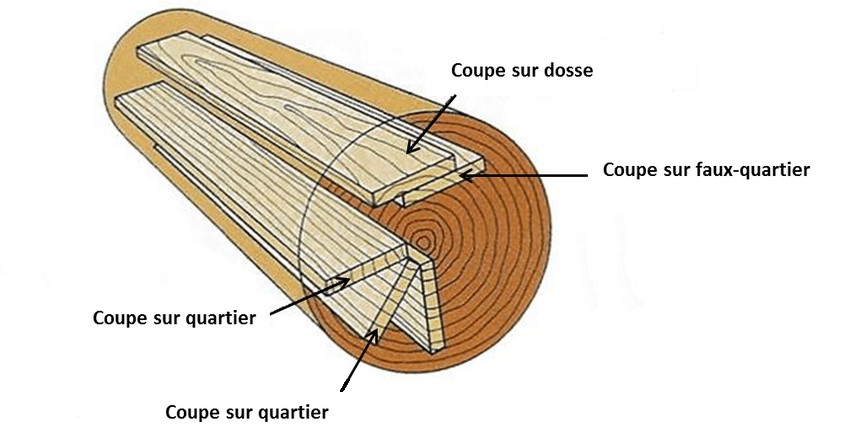

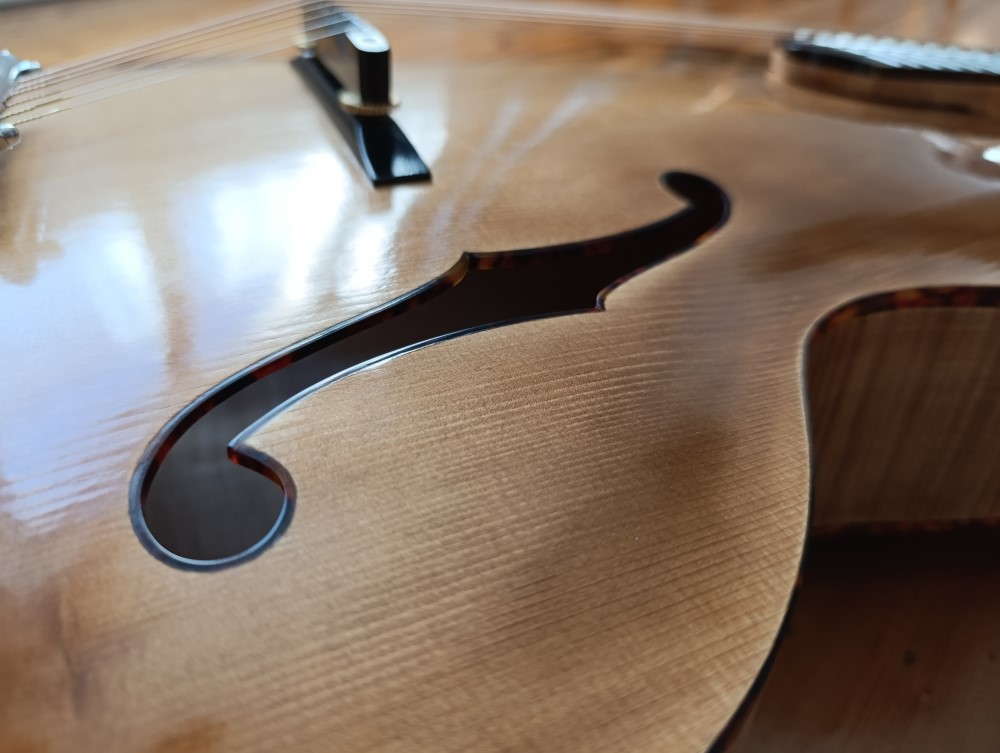

| You can see from

the image below that the rings are perpendicular to the faces, which is essential for optimal soundboard fibration. |

Here you can see the difference with wood on slab and on false quarter where the rings are not perpendicular to the faces. | |

|

|

|

The pencil allows

you to visualize the thickness required to sculpt the vaulted faces. |

||

As for the back and sides of the guitar, these pieces of wood also have an impact on the sound of the instrument. Working in resonance, they reflect the sound which is then expelled through the sound holes, but in the process they instill a different character depending on the wood used, which has differences in its density and grain and also influence the strength of the projection, the duration and the brilliance of the sound. To get the best out of these different elements, you need a wood with high density and rigidity. Several woods have these characteristics, then comes the choice in terms of the wood's aesthetics. I'll take the case of maple the more it's flamed, the harder it is and the more beautiful it is. Maple back and sides, paired with a spruce top, will develop a brightness and tonal clarity with clear notes and excellent sustain. |

||

| On this piece of maple with beautiful waves you can still see the quarter cut as well as the thickness needed to sculpt the arched back. | ||

|

||

| And the result after several months of work !!! | ||

|

||

|

||

| Finally,

the woods used to make the fingerboard and bridge. Here again, the

choice of wood will influence not only the final sound of the

instrument, but also its durability. In fact, the fingerboard is

subjected to the repeated rubbing of steel strings, and is also

attacked by the acidity of the musician's sweaty fingers. Therefore, you need a wood with tight fibers to prevent the absorption of finger sweat and also a wood that is dense and hard so that it does not become dented by the repeated rubbing of the steel strings. Ebony is particularly suitable here because it meets all the criteria. It is one of the densest woods in the world, so it resists wear well, and its hardness also contributes to producing more percussive and precise notes, again offering better sustain. What's more, its black color contrasts well with the lighter woods and with the inlays in Abalone or mother-of-pearl. The same applies to the bridge, where the high density of the ebony ensures good transmission of vibrations to the top, and a sharper, more precise attack. |

||

| Here is a piece of planed ebony where you can see the density by looking at the edge. | Here the ebony bridge in place on the top. | |

|

|

|

| Here is an ebony inlay to reinforce this part but also for aesthetics. | ||

|

||

To contact the Workshop : 16 rue Saint Clair 56 950 Crach Bretagne, FRANCE E-mail : d.simon.lutherie@gmail.com |

||